Last Updated on

Construction Crane Operation Safety

Occupational Safety and Health Administration (OSHA) defines the term “crane” as construction machinery used to hoist, lower, and move a load.

Cranes have various types and lifting capacity. Some common construction crane types include tower cranes, mobile cranes, crawler cranes, all-terrain cranes, etc. While lifting capacity is usually measured by tons. For example, Tower cranes with 10 ton lifting capacity.

In today’s manufacturing and construction industries, crane has become one of the must-have machine to use, you can always spot at least one crane on construction site. However, the use of cranes also comes with potential safety risk that can lead to injuries, fatalities and costly damage, for example crane collapse, falling load, and many more.

The good news is this risk can be prevented as long as there is a proper crane safety procedures including a correct crane assembly, trained crane operators, secure loads and lifting, etc.

5 Important Things to Note for Construction Crane Safety

To ensure construction safety, here are the top 5 must check points before starting operation:

- Qualified Crane Operator & Personnel : crane operator must be familiar with the crane model, its characteristics, lifting capacity and limitations. Operators are responsible for safety as soon as they begin operating and lifting a load. Besides crane operators, all on-site personnel also needs to properly trained and experienced in carrying out their given tasks.

- Clear Communication : communication between crane operators and on-ground personnel is important especially during lifting. Some ways to communicate includes hand and body signals, horns(usually for emergency or alerting situation), or radio communication. Radio communication is the most commonly used in construction site.

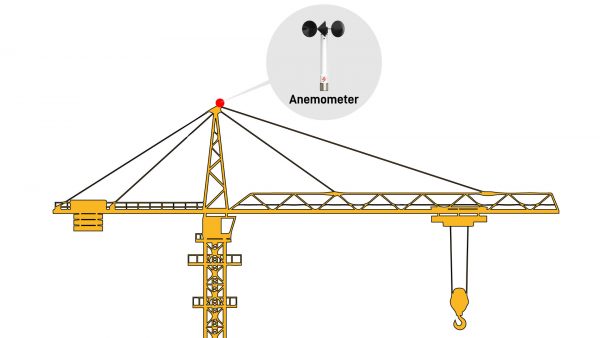

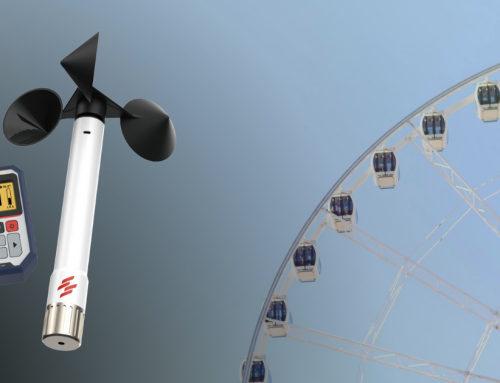

- Load Lifting & Swing Radius : every crane has a swing radius, the distance which the boom and counterweight travel. When the radius is identified, close off an area equal to this to create a control zone, so no unauthorized people are put in danger. Also, circumstances are different every time a load is lifted. Always review weight load capacities, crane equipment capabilities, and the environment before lifting. Other factors such as wind speed and direction also have a direct impact in lifting safety and load direction.Crane operator can get real time wind speed data by using anemometers (wind speed meters). WR3-Plus Wireless Anemometer is one of the best and most cost-effective wind speed measuring tool that crane operators love! It is suitable for all crane types. Learn more here.

- Weather : Weather also plays a role in determining whether it is safe to operate crane or not. Hot, cold, or rainy weather may poses a certain safety risk depending on how extreme it is. Therefore, before operating crane, personnel needs to assess the weather condition and make sure it is safe enough to operate the crane.

In conclusion, safety always comes first especially when operating cranes in construction site and any other job sites. Here is a crane safety checklist that you can use to make sure all safety standard is checked before crane operation.

BONUS: Free Download Crane Safety Checklist (click to download).

Looking for a high-quality wireless wind speed meter for your cranes? Check out the best-selling wind speed meter for all cranes types – WR3-Plus model (click for more information).