Know How –

Heat Stress Management with Real-Time Monitoring Solutions

Heat Stress Management: A Growing Concern for Modern Workplaces

The rising frequency of heat-related illnesses is a real concern that demands immediate attention. Imagine your workforce as a high-performance engine. Heat stress is the equivalent of running that engine in the red zone—it leads to overheating, and that creates a cascade of problems.

Now, what does heat stress entail? A spectrum of conditions from mild rashes and cramps to severe heat strokes and exhaustion. As global temperatures continue to climb, workplaces—especially those outdoors or in hot environments—are increasingly under the heat lamp. Simply put, more exposure equals a greater risk for workers.

Challenges of Manual Heat Safety Practices

Late Detection of Symptoms

Workers might not recognize the symptoms of heat stress early enough, leading to severe health outcomes such as heat stroke or exhaustion. By the time signs become apparent, the condition may already require immediate medical attention, which only puts worker health at high risk.

Absence of Real-Time Environmental Data

Manual methods do not provide online continuous monitoring of environmental conditions, which can rapidly change, especially in outdoor settings like construction sites or agricultural fields. Without real-time data, sudden temperature spikes or humidity changes may go unnoticed, and this increases the likelihood of heat-related incidents.

Insufficient Monitoring of Workers’ Compliance

It’s challenging to ensure all workers adhere to hydration and rest policies without consistent monitoring and reminders. Supervisors may struggle to track individual compliance, especially in large teams. This leaves room for lapses in protocol.

Our Dual Approach to Heat Stress Monitoring

Scarlet Tech offers two advanced solutions to manage heat stress effectively: the TWL Heat Stress Meter and the Online Heat Stress Weather Station.

TWL Heat Stress Meter

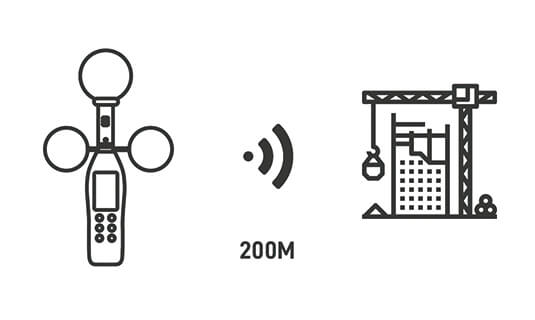

Ideal for field teams, this portable device enables quick, accurate assessments of TWL, globe temperature, and humidity—key indicators of heat stress. Its compact design allows easy transport, while real-time data supports prompt decision-making to protect workers from heat-related risks.

Online Heat Stress Weather Station

Designed for fixed locations like factories and construction sites, this system delivers continuous monitoring and automated alerts. Remote access ensures you’re always informed, and its data can be integrated into safety protocols to enhance workplace protection.

Together, these tools provide both on-the-go and long-term solutions for safeguarding teams in high-temperature environments.

Compare the Solutions: Which One Fits Your Needs?

| Feature | TWL Heat Stress Meter | Online Heat Stress Weather Station |

| Portability | Yes | Fixed installation |

| Real-time alerts | Yes (On device) | Yes (Remote alerts) |

| Data logging | Yes | Yes (Cloud-based) |

| Ideal for | Field teams | Centralized monitoring |

Choosing the right solution depends on the specific requirements of your operations. The TWL Heat Stress Meter is excellent for dynamic and mobile teams needing on-the-spot assessments, while the Online Heat Stress Weather Station is ideal for settings where you need round-the-clock, remote monitoring without disruption.

Compliance & Safety Made Easier

Both solutions from Scarlet Tech support compliance with OSHA, ISO 7243, and other international heat stress management guidelines. Real-time data provided by these tools help plan and optimize rest and hydration schedules for workers, reducing the risk of heat-related illnesses.

Additionally, documented data can assist in liability reduction and meeting audit requirements, providing a comprehensive record of the environmental conditions and the proactive steps taken to ensure worker safety.

Industries that Benefit Most from Our Solutions

Various high-risk industries where workers are routinely exposed to extreme heat can greatly benefit from Scarlet Tech’s heat stress management solutions:

- Construction

- Agriculture

- Logistics

- Manufacturing

- Event Management

- Military

- Mining

- Oil & Gas

Scarlet Tech’s tools take safety protocols from reactive to proactive. You’ll protect your workforce, maintain compliance with safety standards, and avoid costly incidents. Think of it as the ultimate strategy to stay cool under pressure.

TWL-1S

Scarlet TWL-1S is designed to measure WBGT and thermal work limit (TWL) heat index. The TWL measures air temperature, humidity, radiant heat and wind speed to come up with instructions for work, rest and hydration plan. We integrate the algorithm of TWL and work-rest schedule based on the latest guideline. The user-friendly interface even showed different colors to ensure users in line with TWL schedule. For example, red means unsafe for work, yellow means buffer zone and green means safe for work.

TWL-1S Heat Stress Monitor

Class 1 sound level meter

What is a Class 1 Sound Level Meter?

A Class 1 Sound Level Meter is a noise measurement instrument that meets the requirements of IEC 61672-1:2002 (or an equivalent such as BS EN 61672-1:2003) to Class 1 performance.

This standard specifies two levels of performance, Class 1 and Class 2, with Class 1 being effectively more accurate. Within the standard are a set of performance criteria that an instrument must meet and each of these has a tolerance associated with it. At the reference frequency of 1kHz, the tolerance limits for Class 1 are +/- 1.9dB and for Class 2 the tolerance is +/- 2.2dB.

Intrinsic Safety

Official Safety Standard for Explosion-Proof

Outside of North America, ATEX (Appareils destinés à être utilisés en ATmosphères EXplosives) and IEC (International Electrotechnical Commission) provide standards that are recognized internationally.

These organizations, unlike FM, UL and CSA, do not perform their own testing but rather have notified bodies to perform the testing to meet the standards they set. To make their products applicable to international businesses, many North American companies will certify their products to ATEX and/or IEC standards in order to make them applicable to international businesses.

Other Know Hows

Class 1 sound level meter

What is a Class 1 Sound Level Meter?

A Class 1 Sound Level Meter is a noise measurement instrument that meets the requirements of IEC 61672-1:2002 (or an equivalent such as BS EN 61672-1:2003) to Class 1 performance.

Intrinsic Safety

Official Safety Standard for Explosion-Proof

Outside of North America, ATEX (Appareils destinés à être utilisés en ATmosphères EXplosives) and IEC (International Electrotechnical Commission) provide standards that are recognized internationally.