Case Study – Wireless Crane Camera

HerculesPro Enhances Visibility & Communication During Dry Bulk Cargo Loading

Dry bulk cargo often faces operational challenges in visibility and communication. To tackle these issues, vessels like Gerdt Oldendorff use the HerculesPro Wireless Crane Camera to improve operations.

Background

Dry bulk cargo transports often faces operational challenges. Limited visibility inside cargo holds, compounded by environmental dust, hinders crane operators’ to see clearly during loading. Additionally, communication gaps between crane operators and ground teams might lead to errors, resulting in vessel damage and higher maintenance costs. To address these challenges, a solution that provides live video feeds of the cargo hold and boom tip is needed.

Solution

HerculesPro has been deployed on vessels like the Gerdt Oldendorff, ensuring comprehensive monitoring and safety during cargo handling.

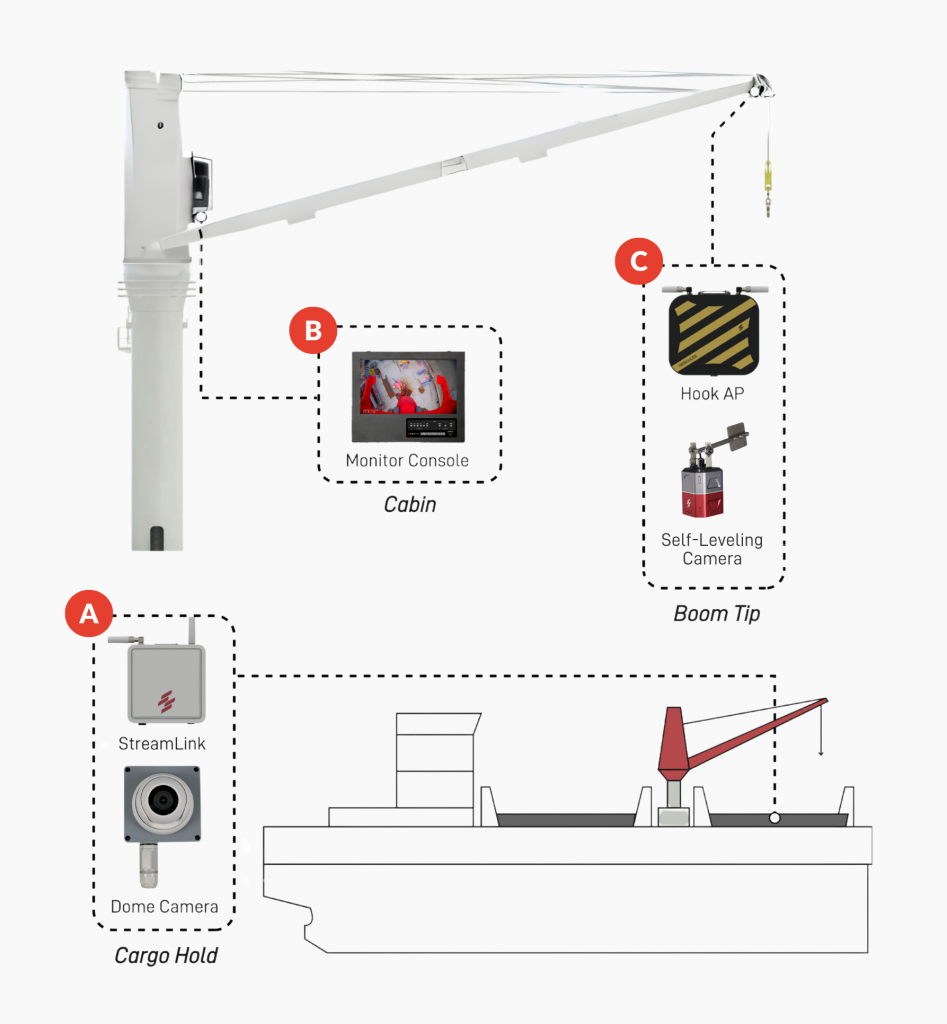

In this vessel, the HerculesPro system is installed at three key locations: the boom tip, cargo hold, and cabin. The key components include the StreamLink and dome camera in the cargo hold (A), the monitor console in the cabin (B), and the self-leveling crane camera with Hook AP on the vessel’s crane boom tip (C).

- Cargo Hold: A dome camera was positioned to capture a wide-angle view of the loading and unloading process. The StreamLink device was implemented to seamlessly transmit real-time video and data from the cameras to the operator’s cabin.

- Cabin: All video feeds were displayed on the monitor console in 2K resolution in the cabin, giving the crane operator clear visibility of the entire operation.

- Boom Tip: Self-leveling crane camera and Hook AP were installed to provide automatic adjustment of viewpoint & real-time visuals of the cargo handling process, enhancing precision and safety.

This installation provides operators with clear visibility into the cargo holds, making HerculesPro an ideal solution for application in the shipping and logistics industry.

Pick a perfect Anemometer

How to Choose the Perfect Anemometer for Construction Site Safety?

Choosing anemometers is particularly important in situations where loads and equipment will be raised significantly above the ground or building.

Heat Stress

What is Heat Stress?

Heat stress is the effect that the thermal environment has on a person’s ability to maintain a normal body temperature. Inability to get rid of body heat adequately may result in heat illness.

Case Study – Wireless Crane Camera

HerculesPro Enhances Visibility & Communication During Dry Bulk Cargo Loading

Dry bulk cargo often faces operational challenges in visibility and communication. To tackle these issues, vessels like Gerdt Oldendorff use the HerculesPro Wireless Crane Camera to improve operations.

Background

Dry bulk cargo transports often faces operational challenges. Limited visibility inside cargo holds, compounded by environmental dust, hinders crane operators’ to see clearly during loading. Additionally, communication gaps between crane operators and ground teams might lead to errors, resulting in vessel damage and higher maintenance costs. To address these challenges, a solution that provides live video feeds of the cargo hold and boom tip is needed.

Solution

HerculesPro has been deployed on vessels like the Gerdt Oldendorff, ensuring comprehensive monitoring and safety during cargo handling.

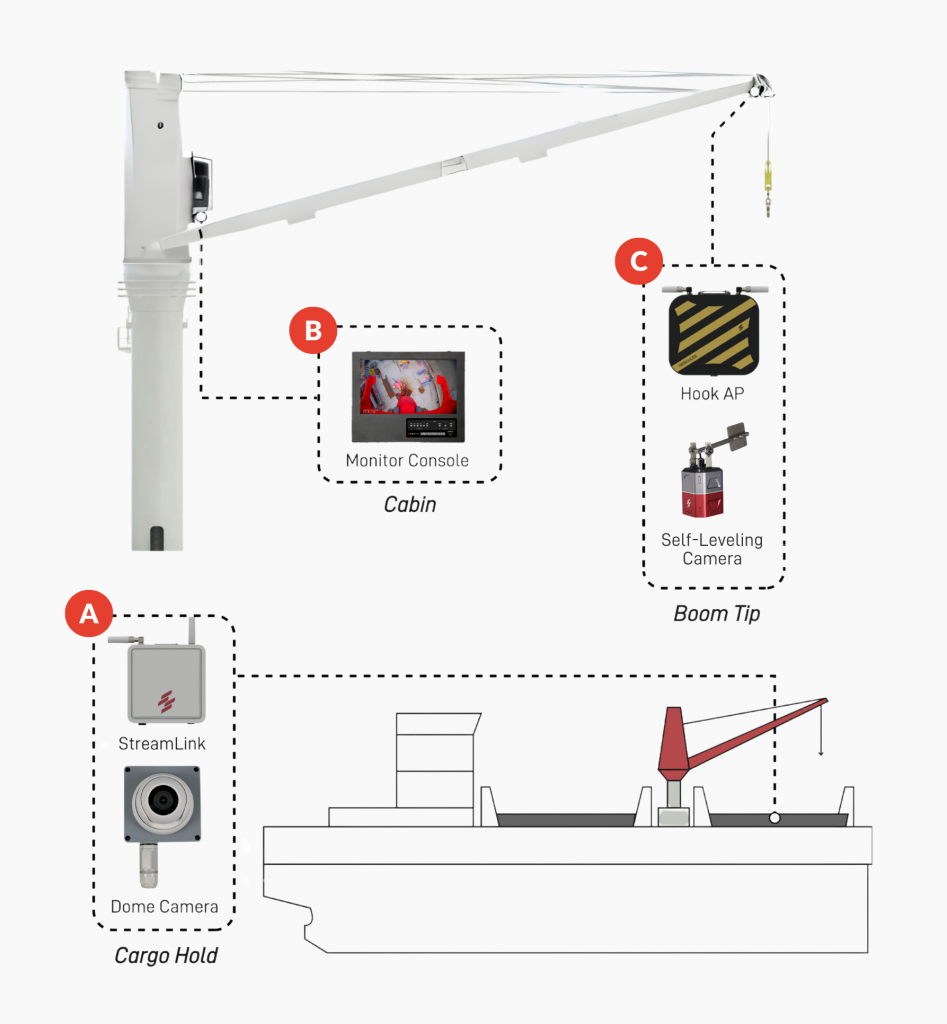

In this vessel, the HerculesPro system is installed at three key locations: the boom tip, cargo hold, and cabin. The key components include the StreamLink and dome camera in the cargo hold (A), the monitor console in the cabin (B), and the self-leveling crane camera with Hook AP on the vessel’s crane boom tip (C).

- Cargo Hold: A dome camera was positioned to capture a wide-angle view of the loading and unloading process. The StreamLink device was implemented to seamlessly transmit real-time video and data from the cameras to the operator’s cabin.

- Cabin: All video feeds were displayed on the monitor console in 2K resolution in the cabin, giving the crane operator clear visibility of the entire operation.

- Boom Tip: Self-leveling crane camera and Hook AP were installed to provide automatic adjustment of viewpoint & real-time visuals of the cargo handling process, enhancing precision and safety.

This installation provides operators with clear visibility into the cargo holds, making HerculesPro an ideal solution for application in the shipping and logistics industry.