In the construction sector, ensuring safety is crucial; however, blind spots, a commonly neglected hazard, pose significant risks to workers and vehicles. In this article, we will explore the concept of blind spots, particularly in construction sites and how they impact safety. By emphasizing the importance of addressing and sharing various solutions, we aim to raise awareness and minimize the risk of accidents associated with these unseen areas.

What Exactly Are Blind Spots?

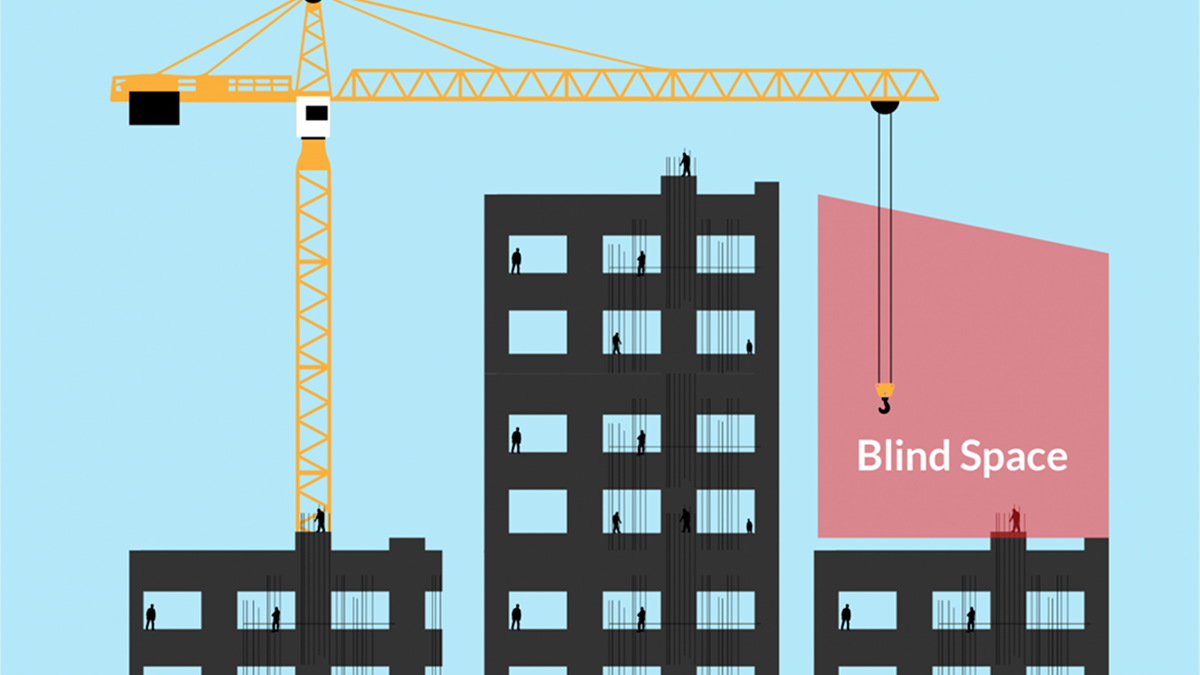

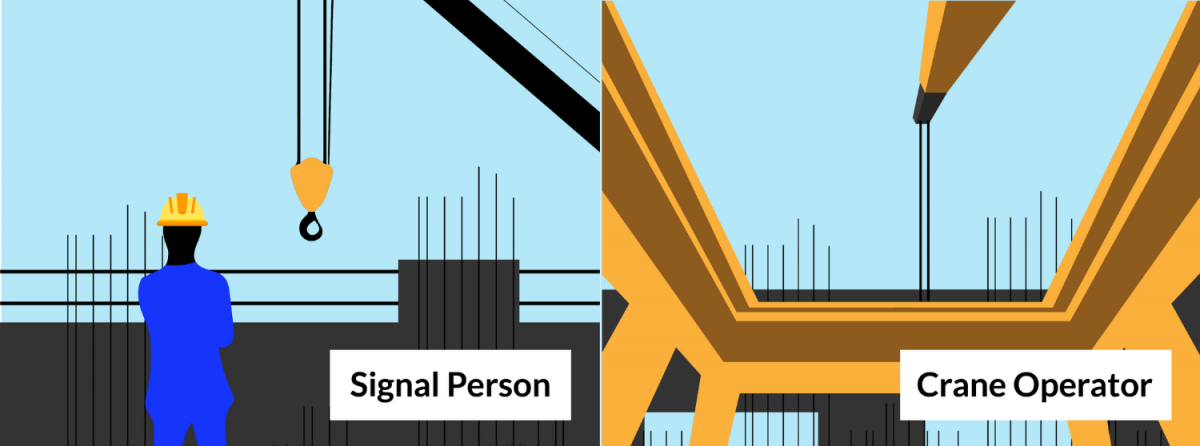

Blind spots are the areas around a vehicle that are not directly visible from the driver’s seat. Today, “blind spots” are more often understood as “vehicle blind spots”. The image below showcases the viewpoints of the signal person and crane operator, emphasizing the limited visibility that persists for crane operators.

Addressing Blind Spots is Crucial for Safety

Blind spot-related accidents may be more frequent than we predicted. According to a study conducted by the University of Michigan Transportation Research Institute on prioritizing improvements in truck drivers, it was discovered that around 20% of crashes were caused by the restricted visibility experienced by truck drivers.

In 2006, National Transportation Safety Board issued a letter to National Highway Traffic Safety Administration (NHTSA) to take action on the mitigation of blind spots. NHTSA is aware of the hidden concern of blind spots, as is the National Institute for Occupational Safety and Health (NIOSH). The NIOSH lists blind area diagrams of construction vehicles, including various kinds of dump trucks, loaders, and scrapers, etc.

Are Blind Spots Inevitable?

We have discovered that blind spots can occur on many construction vehicles.

In general, the taller and longer the vehicle, the bigger the blind spots. Compared to trucks and mobile cranes, tower cranes pose significant blind spot challenges, let alone human eyesight limitations and sun blind caused by the weather conditions.

What Are The Solutions?

An expanding array of technology is being investigated to address the issue of blind spots and mitigate the potential hazards or reduce the resulting risk. These include Building Information Modeling (BIM) technology, anti-collision systems, collision-detection systems, and tower-crane-mounted live video systems.

Among these solutions, tower crane camera systems are gaining attention due to their ability to save 29% of total traveling time (loading and unloading) at construction sites. Last but not least, it is important to highlight that this is only the measurable quantitative data reported in the study of vision systems for tower cranes, without taking into account the enhanced confidence of the operators.

We Have The Solution

HerculesPro is the tower crane camera system that has been improved and upgraded to fit the market’s needs and expectations. With the latest WiFi 5GHz technology, HerculesPro has overcome a common latency issue in streaming 2K high-resolution video footage over long-range distances.

Contact us for our best price and elevate your construction safety now!

References

- Blind spot (vision) – Wikipedia

- Reed, Matthew P., Daniel Blower, and Michael J. Flannagan. Prioritizing improvements to truck driver vision. No. UMTRI-2005-31. University of Michigan. Transportation Research Institute, 2006.

- Howe, Gavin, et al. Commercial connected vehicle test procedure development and test results–blind spot warning/lane change warning. No. DOT HS 812 317. 2016.

- Shapira, Aviad, Yehiel Rosenfeld, and Israel Mizrahi. “Vision system for tower cranes.” Journal of Construction Engineering and Management 134.5 (2008): 320-332.

- Visibility Around Heavy Vehicles – SAAQ (gouv.qc.ca)Zhang, Mingyuan, Rui Shi, and Zhen Yang. “A critical review of vision-based occupational health and safety monitoring of construction site workers.” Safety science 126 (2020): 104658.